Trusted by Global Industry Leaders

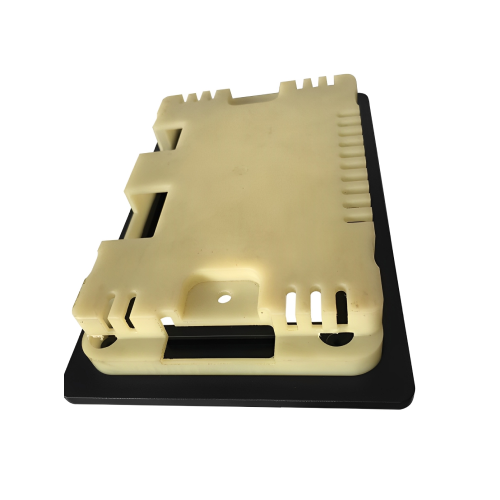

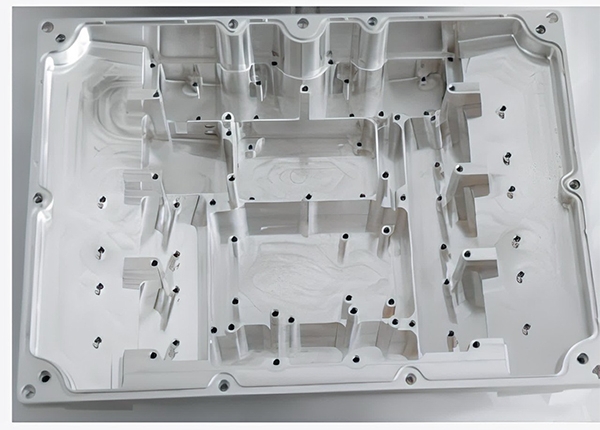

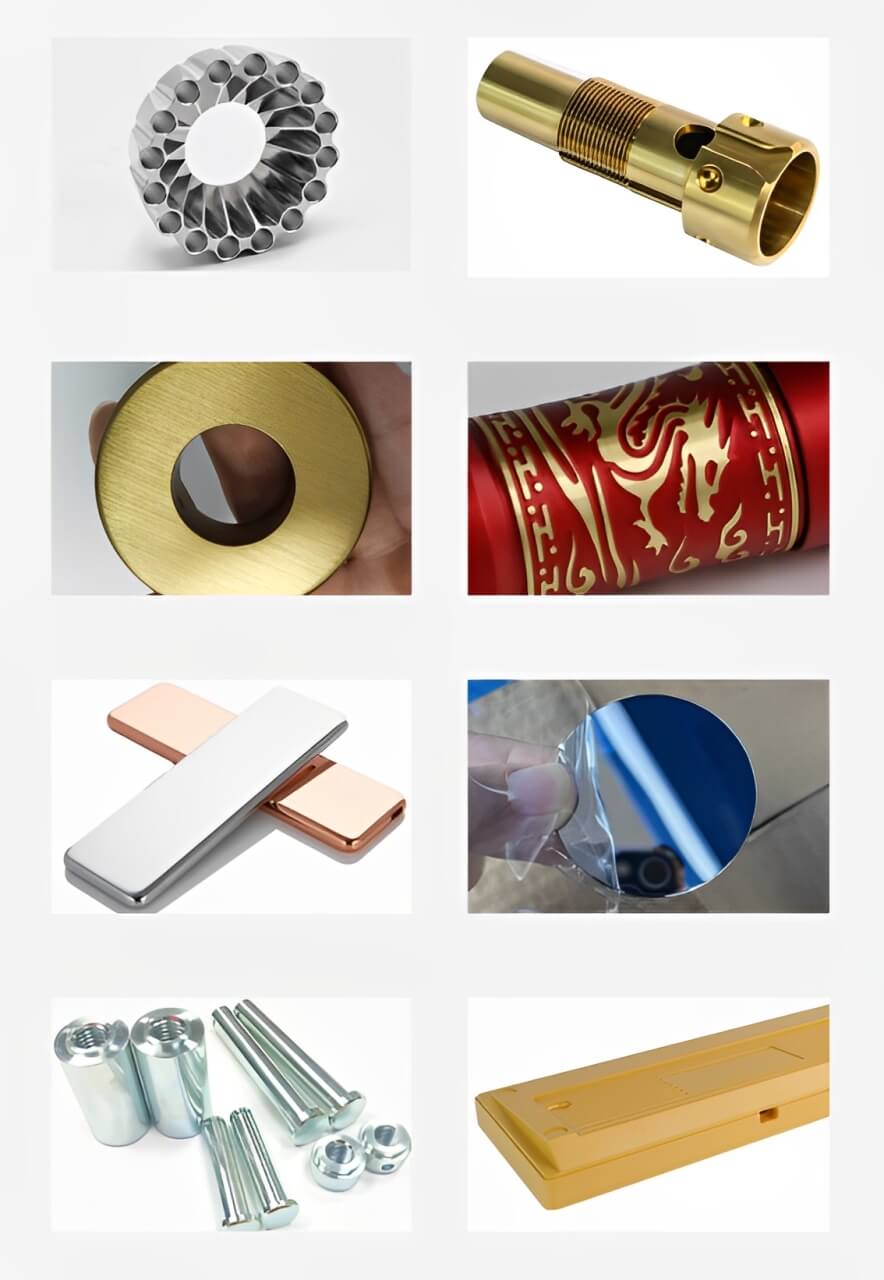

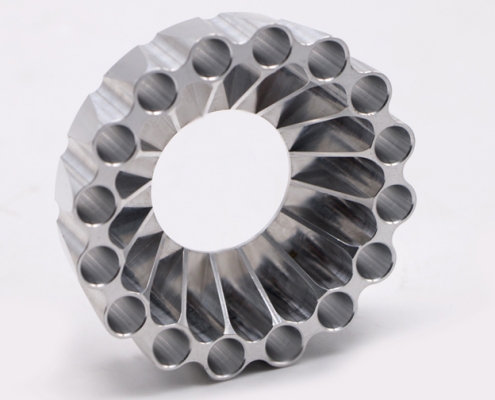

Our Custom CNC Prototype Products

We specialize in manufacturing high-quality metal and plastic prototypes, ensuring exceptional accuracy and craftsmanship in every project. Here are some examples of CNC-machined prototype parts we’ve produced for our customers, shared with their permission. With expertise in high-precision CNC machining, we have successfully delivered over 20,000 unique models.

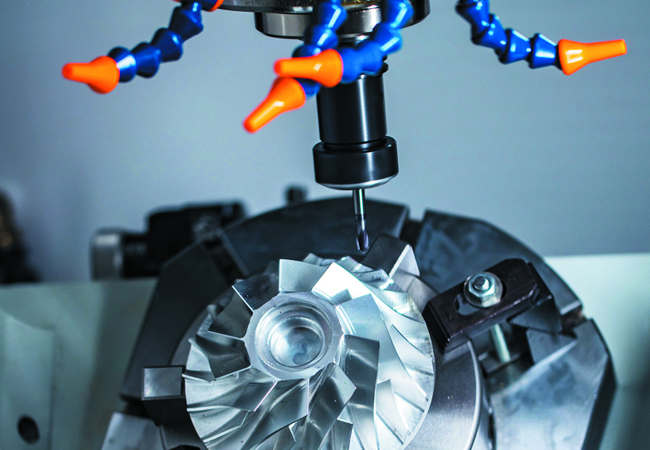

Our Custom Rapid CNC Prototyping Machining Services

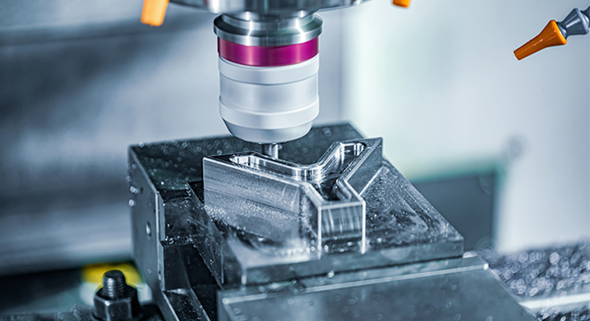

We provide professional rapid CNC prototyping and manufacturing solutions for a wide range of industries, handling even the most complex projects with ease. Backed by an experienced and dedicated project team, we ensure seamless support from start to finish. Our high-quality, precise, and efficient CNC prototyping services are designed to bring your ideas to life and accelerate their journey to market.

CNC Milling

Custom Your CNC Prototype Machining Products

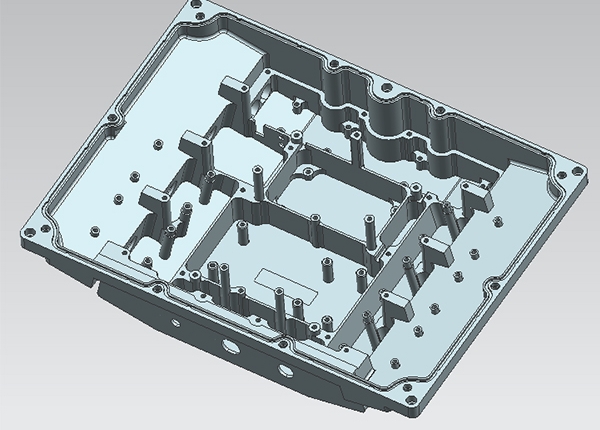

From Concept to Mass Production: End-to-End Customization for CNC Prototype Machining Products

Product design drawing vs Product actual picture

Start your CNC machining prototype project today!

Why Choose VMT for Your Project

Our Production Environment

Choose VMT for high-precision CNC prototype machining – Direct from Our Factory for Better Prices and Higher Profits! With advanced CNC technology and advanced inspection equipment, we ensure precision at every stage.

12-Step Quality Inspection Process

Custom CNC Prototype Machining Materials

Selecting the right material for a project depends on multiple factors, with a key principle being that the material’s performance must meet both the product’s technical specifications and environmental requirements. At VMT, we carefully evaluate application needs to choose the most suitable material, ensuring the optimal realization of your design and the highest product quality.

We collaborate with long-term material suppliers to source SGS-certified materials and work with experienced surface finishing manufacturers with over 10 years of expertise to offer more than 40 finishing options. Our dedicated supplier quality engineer monitors the entire finishing process on-site, ensuring 100 percent inspection of product appearance and strict quality assurance.

Custom Machining Services Surface Finishing

With over 40 advanced surface finishing processes available, our custom machining services deliver more than just precision. We enhance both the appearance and performance of your parts through expert finishing. Our team includes two experienced surface treatment engineers who ensure strict process control and consistent quality across every stage of the surface treatment process.

We offer a wide range of surface finishing options including anodizing, electroplating, painting, and more. Each solution is tailored to meet the functional and visual requirements of your specific CNC machined prototype parts. You do not need to wait. We can quickly provide accurate quotations for different surface finishes after machining. Our goal is to make sure the final finish not only meets but exceeds your expectations in both appearance and performance.

Customer Visit Factory + Exhibitions

We cordially invite customers from around the globe to visit our factory, Shenzhen VMT Metal Product Co., Ltd., located at Building 14, Dawei Shahe Industrial Zone B2, Xinzhuang Community, Matian, Guangming, Shenzhen, China.

Established in 2006, our 5,000-square-meter facility is equipped with over 100 advanced CNC machines, including high-speed CNC lathes, automatic lathes, and 3, 4, and 5-axis CNC machining centers.

Our dedicated team of approximately 100 employees is committed to delivering high-quality, precision-engineered products.

If it is inconvenient for you to come, we can arrange online video conferencing to let you know more our factory? Then you can see if we meet the requirements.

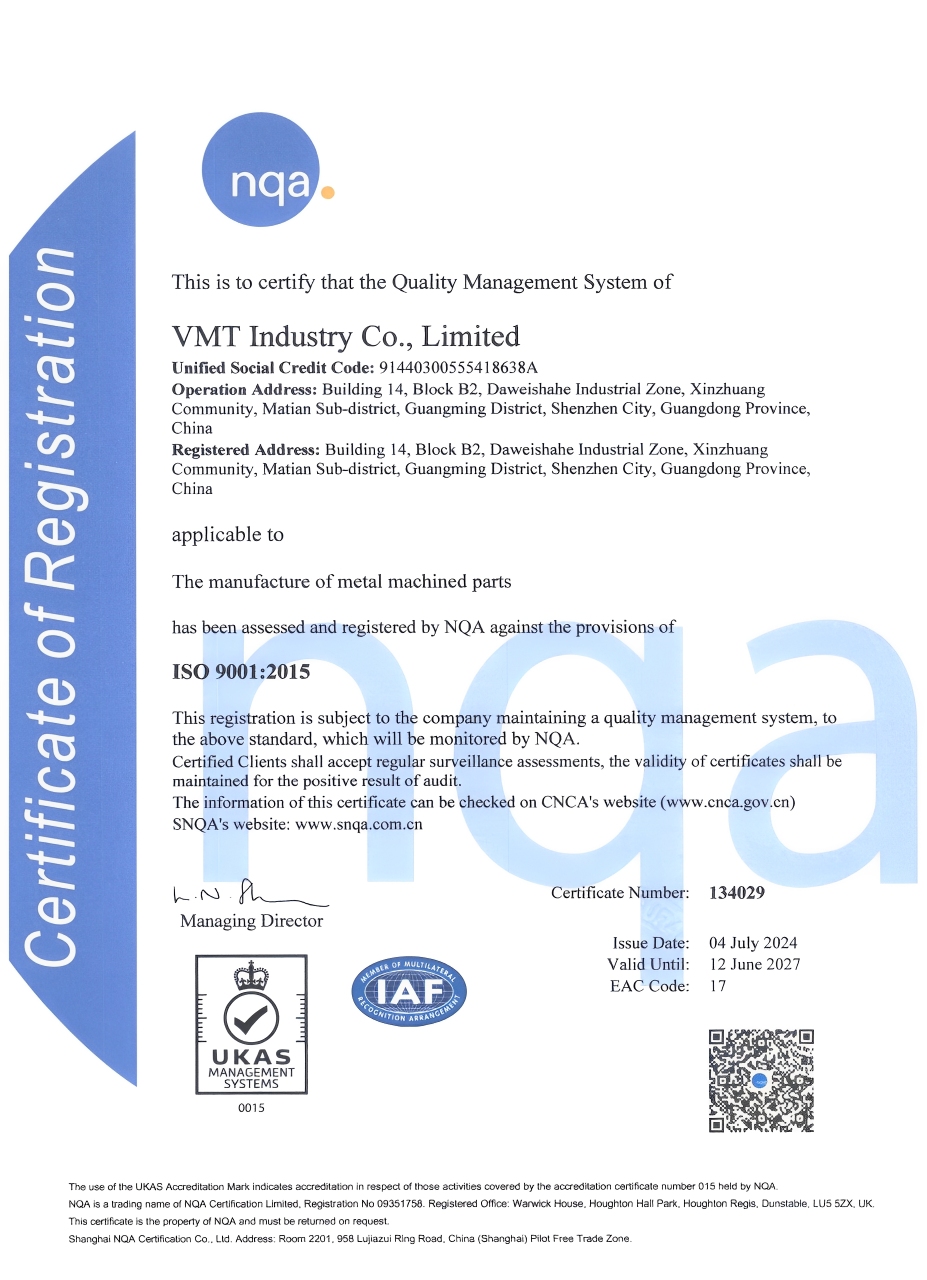

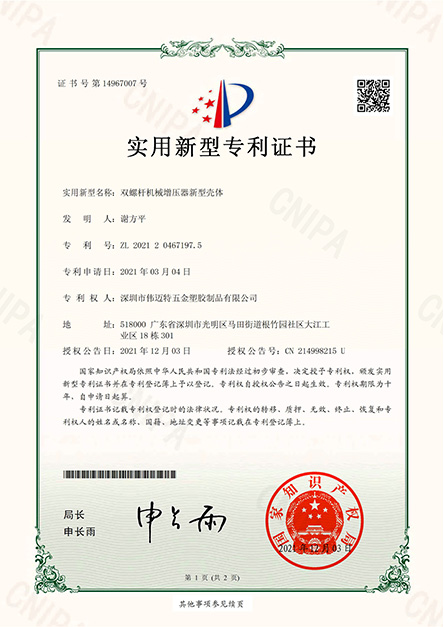

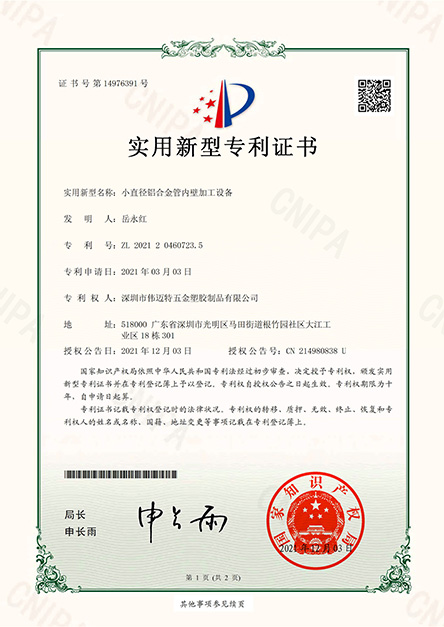

Our Certificate

As a seasoned manufacturer specializing in on-demand CNC prototype machining, VMT is certified in the ISO 9001:2015 Quality Management System and IATF 16949. This ensures that all departments adhere rigorously to these standards for strict production control.

ISO 9001

IATF 16949

SGS

Shell Machining

Aluminum Machining Patent

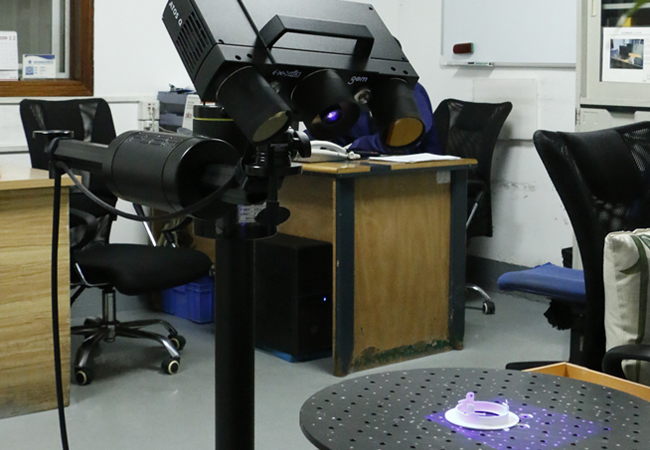

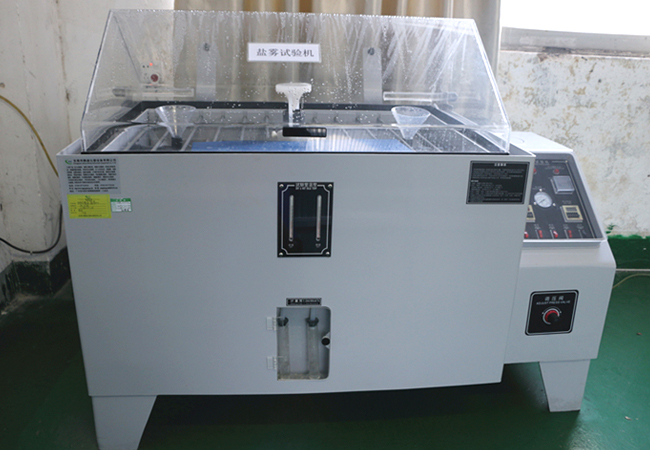

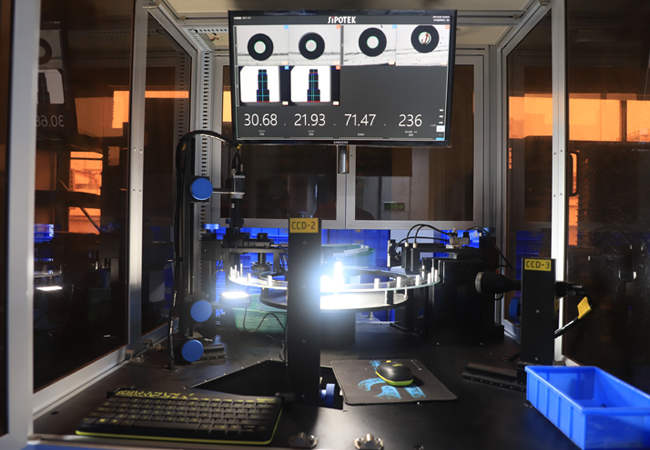

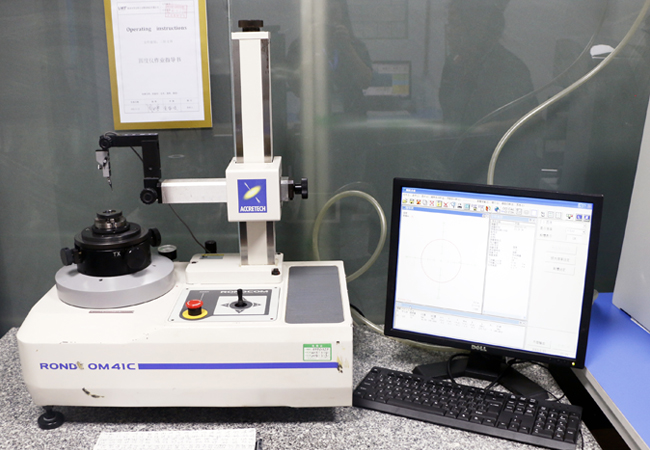

Quality Testing Equipment

Our quality testing equipment includes advanced 3D and 2D measuring instruments, height gauges, thread gauges, and roughness gauges, ensuring precise dimension checks and material compliance. We provide full-dimension inspection reports for each part and retain these records for two years. With capabilities such as CMM inspection, material testing, and certification of conformity, we guarantee exceptional quality and adherence to the highest standards.

Successful Cases CNC Prototype Machining Project

Rapid CNC Prototyping: Delivering High-Precision Aluminum Parts in Just 3 Days

High Precision CNC Machining of Medical Parts

Precision, Quality, and Reliable Service

FAQs about Rapid CNC Prototyping Machining

1. What are your maximum dimensions for CNC prototyping machining?

VMT is proficient in facilitating the production and prototyping of large machined parts, be it metal or plastic. We boast a substantial CNC machining build envelope measuring 2000 mm x 1500 mm x 300 mm. This ensures we can accommodate even sizable parts, including those tailored for furniture or architectural applications.

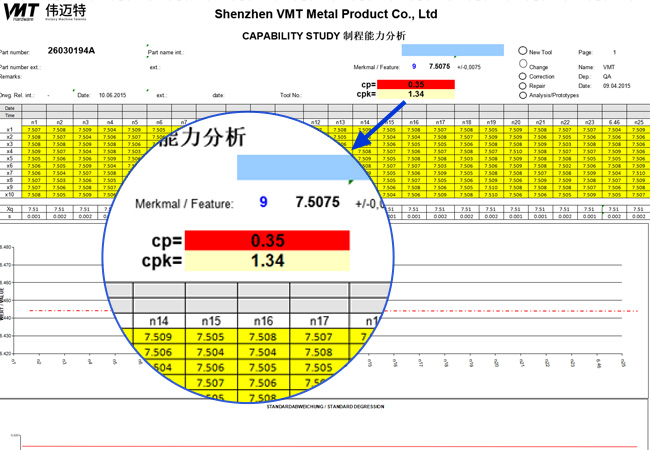

2. Is your CNC prototyping machining quality stable?

We use an advanced quality control system, equipped with manual and automated inspection equipment. All reports are archived and kept for two years, such as first article inspection, process inspection, and shipment inspection. From raw materials, CNC prototyping machining to shipment, We have dedicated personnel to follow up and share progress in real time. We have a testing laboratory equipped 2D projector, 3D projector and other high-precision testing instruments.

3. Are your materials standard? Can you provide material reports?

We all use new and standard materials, not secondary recycled materials. Our material composition is standard and we can provide third-party test reports from SGS, CTI, TUV, etc. Please see the attachment.

4. How do you control the quality of surface treatment?

In addition to conventional surface treatments, there are a variety of special surface treatments. We have a full-time SQE to follow up and control each process in the surface treatment factory. After returning to our workshop, the product appearance will be 100% inspected.

5. What inspection equipment do you have?

We have a testing laboratory equipped with three-dimensional, two-dimensional, projectors and other high-precision testing instruments.

6. Can the delivery date be guaranteed?

At present, VMT is equipped with two processing teams specializing in small batches or samples, which can complete the samples in 24 hours at the earliest, to better serve customers in the early verification stage. At the same time, VMT has 100 devices, which run 24 hours a day to meet the fast delivery requirements of customers. In addition, VMT has a stable outsourcing supplier who has cooperated with us for more than 10 years to assist in fast shipment of samples and large batches. If there is an unexpected delay in delivery, we can bear the relevant costs according to customer requirements.

Trust us with your project. If the quality doesn’t meet your requirements, we’ll refund you within 24 hours.

We ensure top quality with precise 3D/2D project validation, height/thread/roughness gauges, and full-dimension inspection reports.

Contact Us for A Free Quote!

Share your requirements, drawings, and reference images with us. Get a free prototype machining quote and bring your idea to life with precision and quality.